Cart

CUTTING LEAD TIME CURRENTLY 2-3 DAYS APPROX AS OF 5TH JANUARY 2026

( MINIMUM CUT TO LENGTH SIZE 15MM )

* Please note that due to rising costs, our cut to length charges have increased effective January 2026. Quantity discounts will still apply *

Handy Steel Stocks appreciates your continued support.

Note, if your postcode is outside of our " Free delivery " region, we can still offer delivery services to your area. Please contact our sales office for more details call 03 9459 6133

Not all items are stocked - Special Buy-ins have Quantity Limitations & Conditions. Please email or phone to enquire.

You will be CONTACTED by PHONE when your ORDER IS READY for COLLECTION

Channel Hot Dipped Galvanized

Hot Dip Galvanizing is the process of dipping steel into a kettle or vat containing molten zinc. While the steel is in the kettle, the iron in the steel metallurgically reacts with the molten zinc to form a tightly-bonded alloy coating that provides superior corrosion protection to steel. The process is inherently simple and occurs after the steel manufacturing process. It provides a distinct advantage over other corrosion protection methods and is used where a higher corrosive resistance is required. Hot Dipped Galvanized Channel is common used for retaining walls and outdoor structural situations.

-

Available

Available100 X 50 GALVANIZED CHANNEL

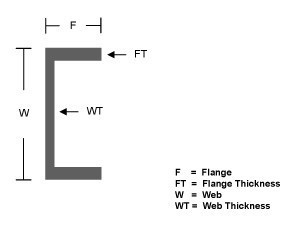

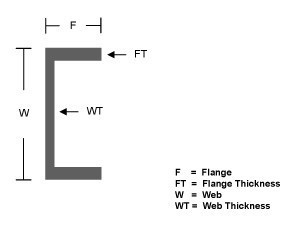

F: 50mm,FT: 6.7mm,W: 100mm,WT: 4.2mm,Kg/mt: 8.33,

F: 50mm,FT: 6.7mm,W: 100mm,WT: 4.2mm,Kg/mt: 8.33,

F: 50mm,FT: 6.7mm,W: 100mm,WT: 4.2mm,Kg/mt: 8.33,

QuantityFull Length - $66.74 GST incl./mt

Mt/Length - 9.00mt

QuantityCut to Size - $70.26 GST incl./mt

(+/- 2mm) +$11.00/cut GST incl. @ mm$600.66 Add to cart -

Available

Available150 X 75 GALVANIZED CHANNEL

F: 75mm,FT: 9.5mm,W: 150mm,WT: 6mm,Kg/mt: 18.5,

F: 75mm,FT: 9.5mm,W: 150mm,WT: 6mm,Kg/mt: 18.5,

F: 75mm,FT: 9.5mm,W: 150mm,WT: 6mm,Kg/mt: 18.5,

QuantityFull Length - $75.55 GST incl./mt

Mt/Length - 12.00mt

QuantityCut to Size - $149.30 GST incl./mt

(+/- 2mm) +$16.50/cut GST incl. @ mm$906.62 Add to cart